Our Solutions

Traditional methods for treating plastic waste, such as recycling, incineration, and chemical degradation, often require high energy and may produce harmful byproducts. Our solution is to use genetic engineering to introduce plastic-degrading enzymes PETase and MHETase into yeast (Saccharomyces cerevisiae) as a replacement for Ideonella sakaiensis. Although Ideonella sakaiensis naturally has the ability to degrade PET plastic, it is challenging to cultivate and scale up for industrial production. In contrast, yeast has well-established cultivation processes, grows rapidly, and is easy to manage, making it highly suitable for large-scale production.

By introducing optimized plasmids carrying PETase and MHETase genes into yeast, we ensure efficient expression of these enzymes within the yeast cells, enhancing their adaptability and degradation capability in plastic-polluted environments. Through genetic modification, these engineered yeast cells can directly degrade PET and other plastics in contaminated environments, breaking them down into harmless small molecules. This innovative approach not only reduces the long-term impact of plastic on soil, water, and marine ecosystems but also offers a low-cost, efficient biological solution for environmental restoration and sustainable development.

Harnessing Enzymatic Power: Use Yeast as a Scalable Alternative for Plastic Degradation

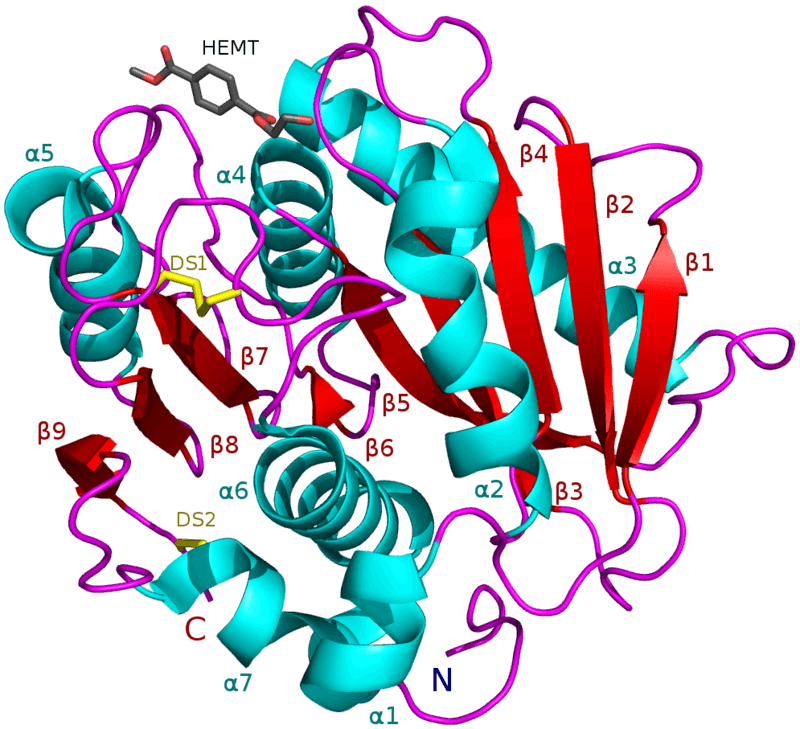

PETase (Polyethylene Terephthalate Hydrolase)

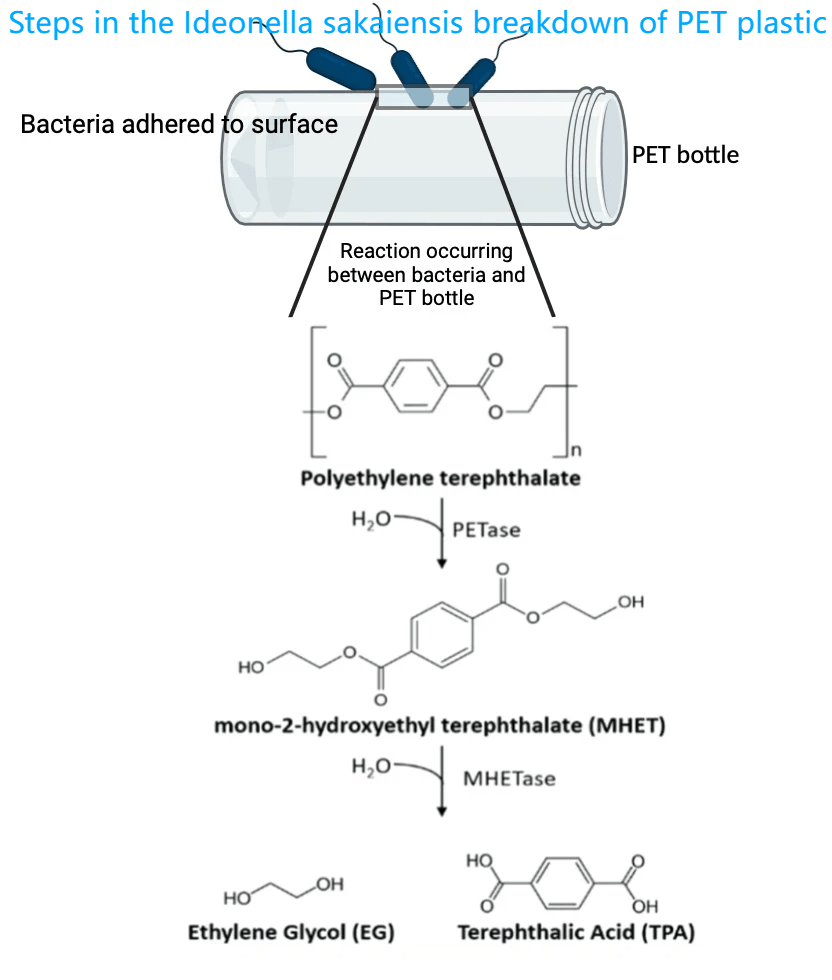

- PETase is an enzyme that specifically breaks down polyethylene terephthalate (PET), a common plastic used in products like plastic bottles and food containers. PET is known for its durability, but this quality also makes it persist in the environment for hundreds of years. PETase was first discovered in Ideonella sakaiensis, a bacterium that evolved the ability to degrade PET naturally.

- PETase initiates the degradation of PET by breaking the ester bonds in the polymer, reducing it to a smaller intermediate molecule which called mono(2-hydroxyethyl) terephthalic acid, or MHET. PETase is unique because it can act directly on the solid PET surface, enabling the initial breakdown of the otherwise resilient plastic.

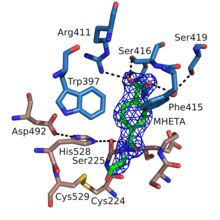

MHETase (Mono(2-hydroxyethyl) Terephthalate Hydrolase)

- MHETase is an enzyme that complements PETase by breaking down MHET, the intermediate product of PET degradation. Discovered alongside PETase in Ideonella sakaiensis, MHETase further degrades MHET into terephthalic acid (TPA) and ethylene glycol, which are harmless, naturally occurring molecules that can be recycled or safely assimilated into the environment.

- After PETase breaks down PET into MHET, MHETase acts on MHET, hydrolyzing it into TPA and ethylene glycol. This two-step process ensures that PET is fully broken down into non-toxic, biodegradable components, completing the degradation pathway and making the molecules available for reuse or assimilation by other organisms.

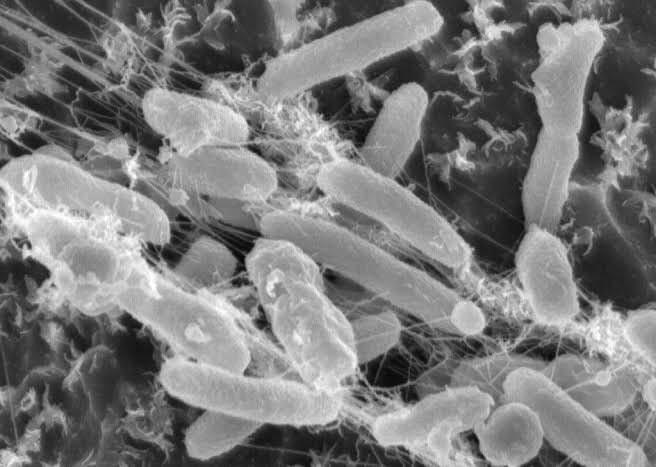

Ideonella sakaiensis

Ideonella sakaiensis is a bacterium that can break down the plastic polyethylene terephthalate (PET). It was first discovered by Japanese scientists in 2016 and has attracted widespread attention due to its unique abilities. Ideonella sakaiensis can degrade PET plastic into harmless small molecules by secreting two enzymes, PETase and MHETase.

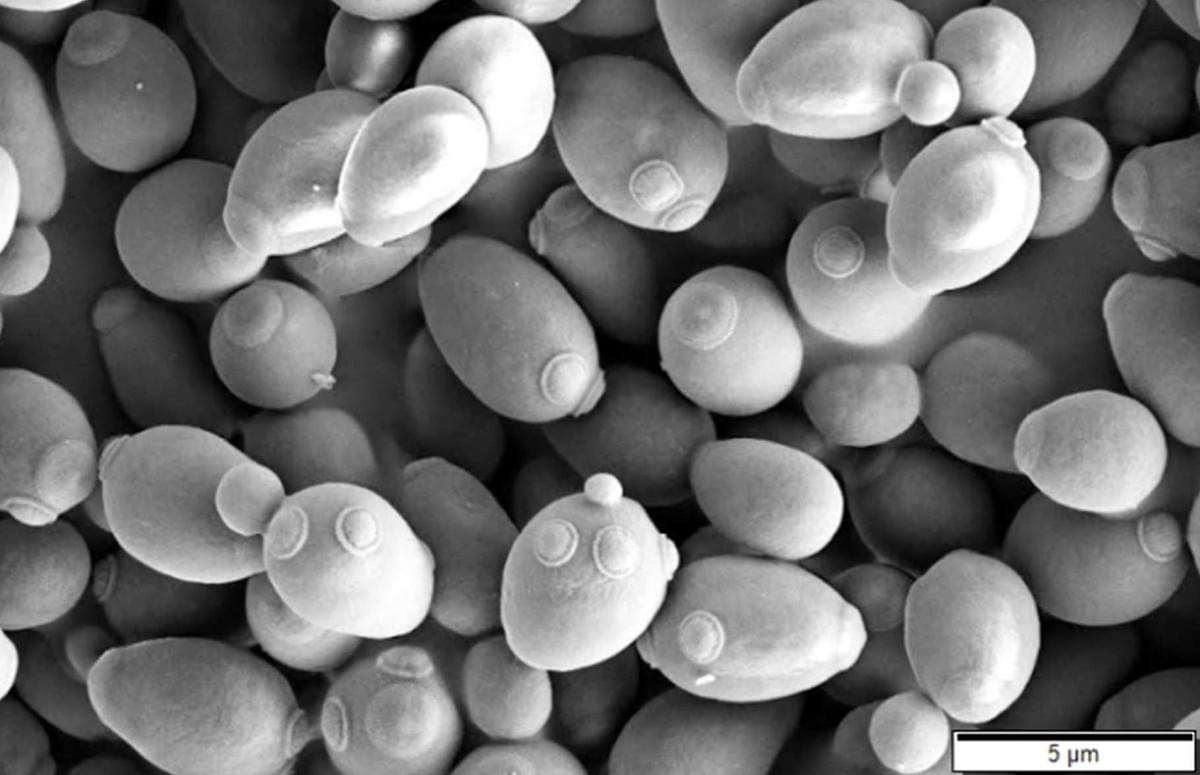

Saccharomyces Cerevisiae (Yeast)

Saccharomyces cerevisiae is a microorganism widely used in food, beverage, and biotechnology industries due to its fermentation abilities and ease of handling. In bioengineering, yeast serves as an ideal host for genetic modifications, with the capacity for rapid growth and suitability for large-scale industrial production. By introducing specific genes, S. cerevisiae can be engineered to break down plastics, offering an innovative solution to environmental pollution. Its flexibility and ease of cultivation make yeast a promising organism for addressing issues like plastic waste in a sustainable way.

How Ideonella Sakaiensis Eats Plastic

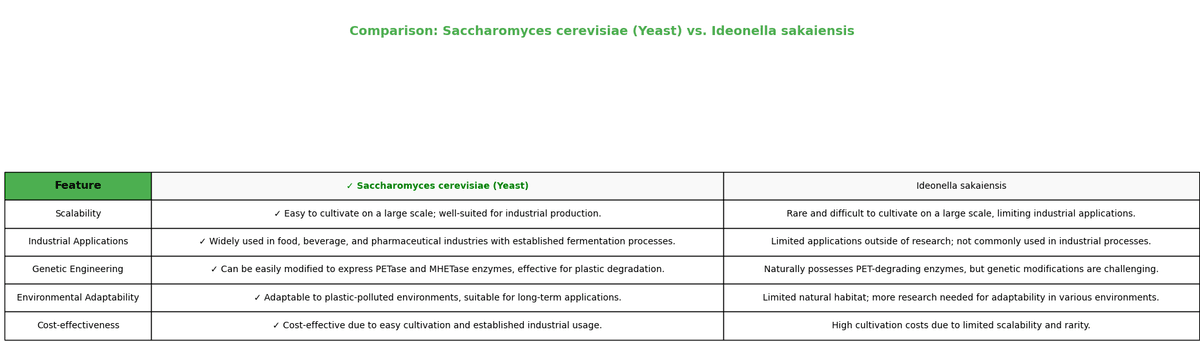

Why Choose Saccharomyces Cerevisiae (Yeast) Over Ideonella sakaiensis?

Flow chart of the process of degrading plastics with Saccharomyces Cerevisiae

Flow chart of the process of degrading plastics with Ideonella sakaiensis

This table compares Saccharomyces cerevisiae (yeast) and Ideonella sakaiensis in terms of various characteristics related to plastic degradation, highlighting yeast as the preferred choice. The “✓” symbol is used to emphasize the advantages of yeast in each category. Compared to Ideonella sakaiensis, yeast is easier to cultivate on a large scale, widely used in industries such as food, beverage, and pharmaceuticals, and benefits from established fermentation processes, making it suitable for industrial production. Yeast is also more accessible for genetic modifications, allowing it to efficiently express PETase and MHETase enzymes and adapt to plastic-polluted environments for long-term applications. Additionally, yeast is cost-effective due to its ease of cultivation, making it a viable and economical choice. Through this comparison, the table illustrates why yeast is a superior alternative to Ideonella sakaiensis for plastic degradation projects.

Advantages of Genetically Engineered Saccharomyces Cerevisiae in Plastic Degradation

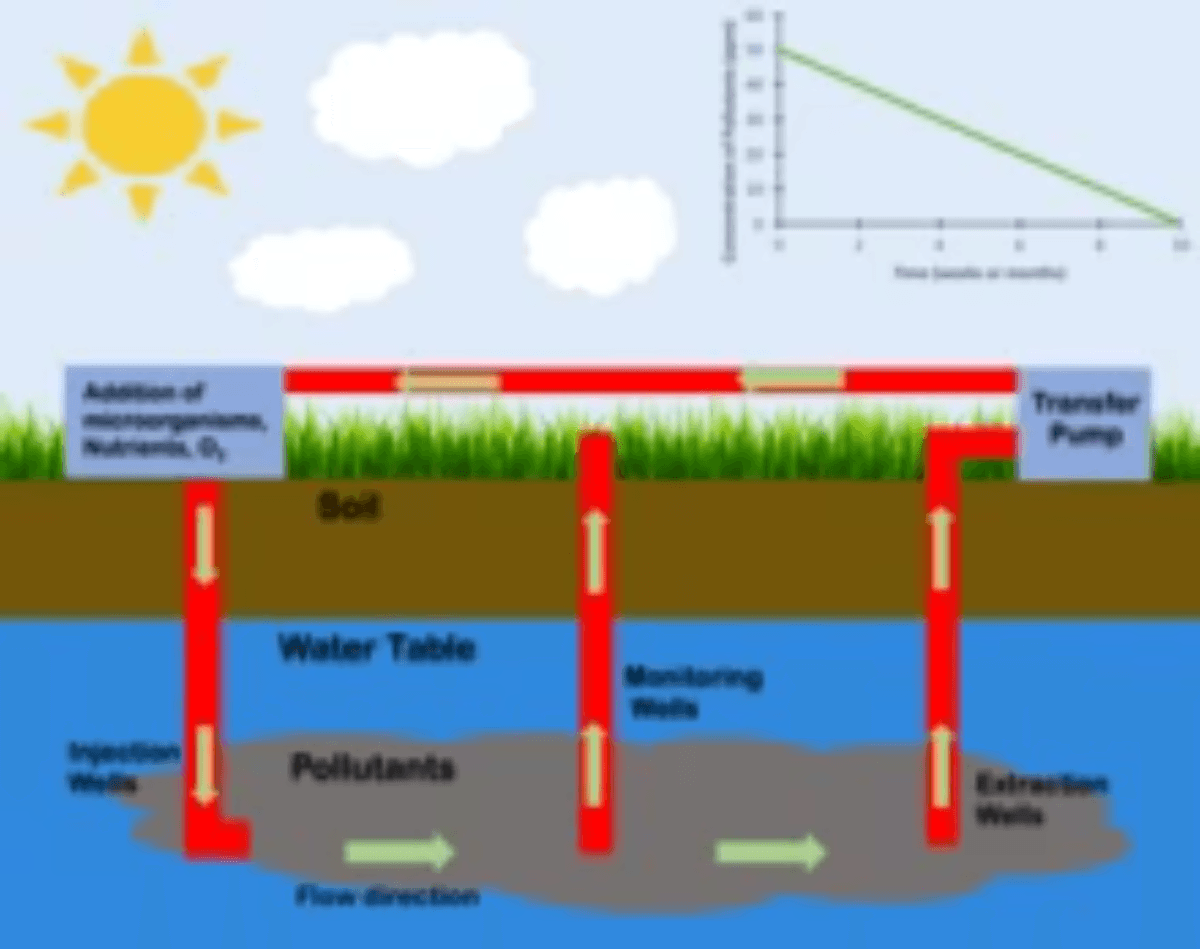

In Situ Degradation

The engineered Saccharomyces Cerevisiae can be applied directly in contaminated areas, such as soil, rivers, or oceans, where it naturally interacts with PET plastic and initiates its degradation. This in situ approach reduces the need for waste transport, mitigating secondary pollution and lowering treatment costs.

Breaking Down PET into Harmless Components

Through the action of PETase and MHETase enzymes, PET is broken down into terephthalic acid (TPA) and ethylene glycol (EG)—non-toxic compounds that pose no environmental threat. Unlike incineration and chemical degradation, this process leaves no harmful residues.

Low Energy Consumption and Sustainability

Operating in ambient environmental conditions, engineered Saccharomyces Cerevisiae requires no high-temperature or high-pressure systems, unlike incineration or chemical processes. This reduces energy costs and aligns with sustainability goals, making it a feasible large-scale solution.

Application in Various Environments

Our engineered Ideonella sakaiensis can adapt to various environmental conditions, including marine and terrestrial ecosystems, making it suitable for both urban waste management and remote ecological preservation efforts.

MCB340 Assignment 3 - Xiuchen Lu